Oil Production Pump

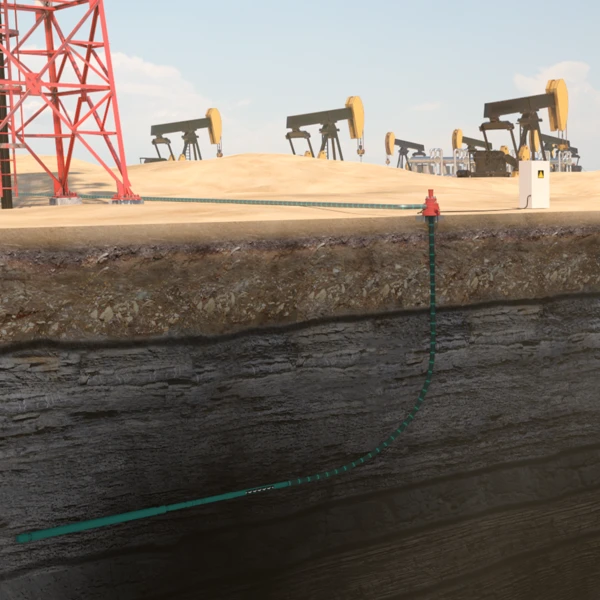

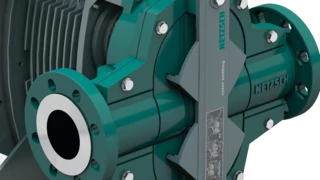

Progressing Cavity Pumps for Upstream Oil Production

Progressing cavity pumps from NETZSCH increase running time threefold

Extracting oil from the ground can be challenging. Depending on the oil field, operators have to contend with a fluctuating consistency of the pumped medium. As a result, most production systems quickly reach their limits, and high failure costs are the result.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems has successfully equipped an oil field with several progressing cavity pumps. We will show you the advantages of using downhole progressing cavity pumps from NETZSCH for oil production.

Individual Consulting

Progressing cavity pumps enable efficient and cost-effective oil production

Global oil reserves are limited and cannot be exploited indefinitely. The pressure on the producing companies to make production as efficient and cost-effective as possible is all the more significant. The classic pumps for oil production, characterised by the "nodding horse head", can still be found in some oil fields worldwide. Still, they no longer represent state-of-the-art, as they have significantly poorer efficiency than other pump technologies. Operators are, therefore, increasingly focusing on progressing cavity pumps. In addition to a greatly improved efficiency, these pumps can handle multiphase media and are extremely flexible concerning the flow rate.

High maintenance due to standard progressing cavity pumps for oil production

Therefore, the BATMAN oil field operators in Turkey opted for this technology. In addition to various pump types from different manufacturers, several downhole progressing cavity pumps from NETZSCH in the standard version were used there. In the standard version, the stator is screwed to the riser pipe at the lowest point. In the second step, the rotor is installed through the riser pipe and the linkage. "However, to replace these units, they have to be elaborately removed together with the riser pipe, which requires the purchase and use of an expensive workover rig", explains Onur Akın, Oil & Gas Upstream, NETZSCH Pumps & Systems Turkey. To reduce the rig costs and shorten the pump replacement time, the responsible parties decided to switch from the standard design to the Insertable downhole progressing cavity pumps from NETZSCH.

Advantages in oil production with progressive cavity pump from NETZSCH

In addition to a tiny outer diameter, these insertable progressing cavity pumps are characterised by the following special features: "They are insertable progressive cavity pumps developed with the main objective of minimising the cost of installing the pumps downhole", Akın explains. "The key feature of these units is their installation through the riser string. The pump is thus not connected to the production line but is installed directly in it." In addition, subsequent pump replacement or maintenance can be carried out using special flush-by equipment. "The pump can be replaced with a rod pull system, which costs significantly less than a complex workover system with special hydraulic tongs for screwing the riser pipes", says Akın. Overall, a significant cost reduction can be realised with this method, as the unit can be removed with the rod pull system through the pipeline. The riser pipe and any existing borehole sensors and sensor cable do not have to be removed. This minimises the time required for workover and thus also reduces production losses by up to 60 percent.

After successfully testing the first two models, the operators installed a third pump. "The client is very satisfied with the result of this project, as not only have the plant costs been reduced, but the service life of the units has also increased. Compared to conventional progressing cavity pumps from NETZSCH, which are not installed inside the pipeline, it has increased by two to three times", Akın sums up.

ESPCP Pump System

- Medium: Oil mixture

- Temperature: 60 °C

- Pressure: 15 bar

- Flow rate: 4,77 m3/d