NEMO® barrel emptying systems are versatile and suction themselves towards the bottom of the barrel. With NETZSCH emptying systems, you can empty your barrels and containers in the chemical, pharmaceutical and food industries almost residue-free.

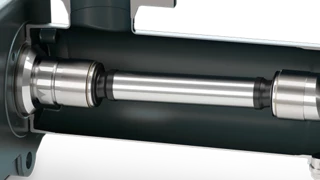

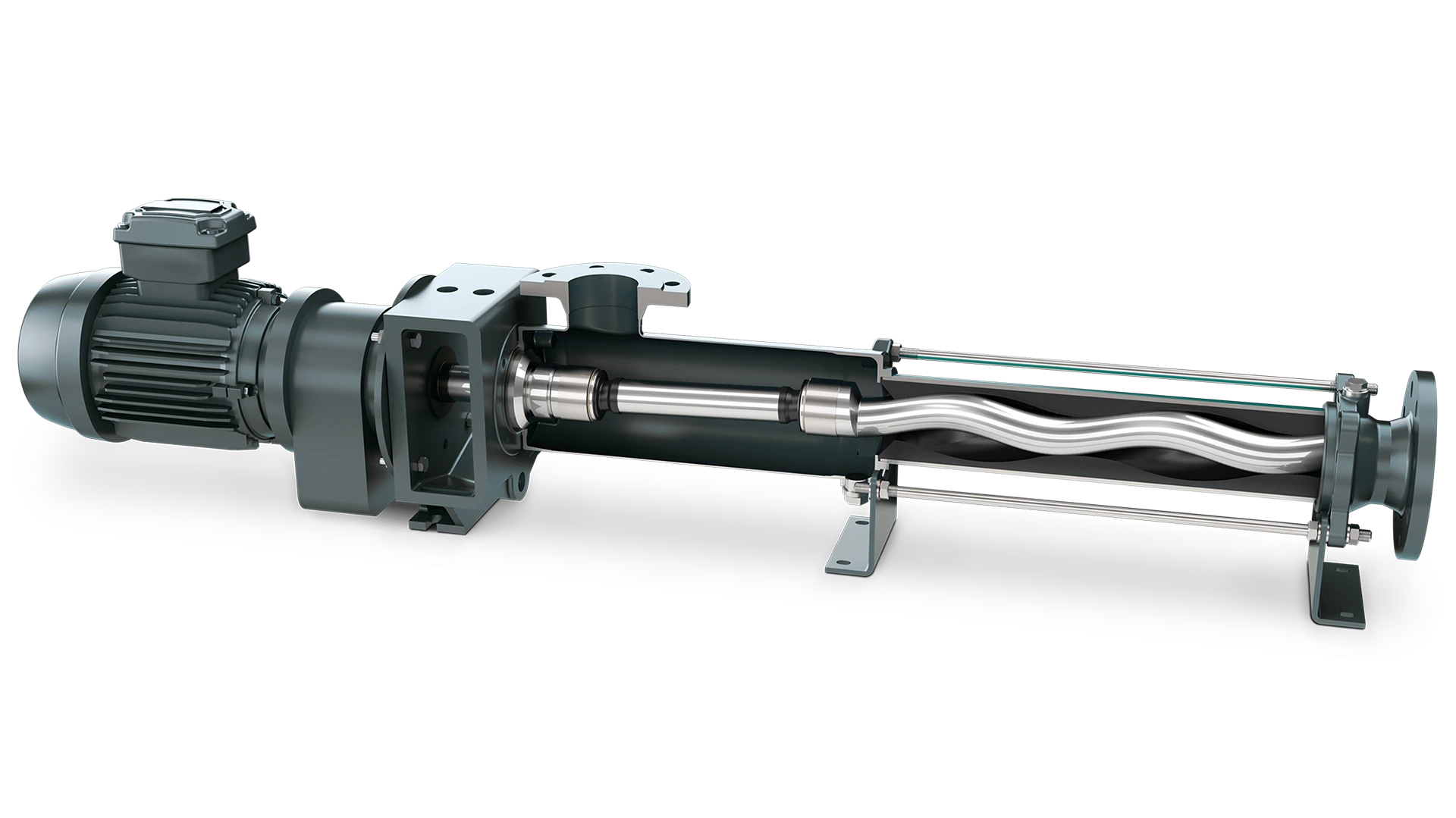

The heart of the system is a NEMO® BY progressing cavity pump, which provides you with constant, low-pulsation pumping. The versatility is wide-ranging: From low-viscosity to barely flowing products, with or without solids content, shear-sensitive, sticky or abrasive, with the progressing cavity pump, you can pump even complex products gently and independently of pressure and viscosity fluctuations. Optionally, the pump can also be heated. This enables you to pump products that tend to harden or require temperature control. When the system is switched on, a vacuum forms under the follower plate. At the same time, this exerts a slight pre-pressure on the product to maintain constant suction. This ensures emptying with a residual quantity of less than one percent of the total content. In this way, you save product and, consequently, money. Another advantage of the NEMO® barrel emptying systems is the possibility of changing the barrel without the system coming to a standstill. This helps you to avoid high downtimes and costs.

Individual Consulting

Advantages

Stainless steel, easy-to-clean design

Low life-cycle costs combined with high serviceability

Delivery rates proportional to speed

Technique

Worldwide service and support for your pump and system

Our service and support do not end with the purchase. From consultation, spare parts and maintenance to the repair and modernization of your pump - we support you right from the start.

Thanks to our worldwide service network, we are ready for you around the clock in case of an emergency.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.