brewer's grains

Pump Hot and Abrasive Brewers' Grains Reliably Over Long Distances

Maintenance-free progressing cavity pump offers you a maximum service life

Are you a brewer or planner of a brewery plant? In that case, you have certainly been faced with the problem of finding the right pump for conveying the brewers' spent grains. Two friends in the USA who share a passion for brewing beer also faced this challenge.

NETZSCH Pumps & Systems provided the remedy. As a global specialist in complex fluid management, NETZSCH offers you innovative solutions for pumping brewers' grains over long distances.

Individual Consulting

Do you want to pump your brewers' grains efficiently over long distances?

Globally, about two billion hectolitres of beer are produced every year and breweries worldwide are faced with the challenge of having to pump the hot and abrasive residues of the brewing malt, the so-called brewers' grains, over sometimes long distances. So are two friends in the USA who share a passion for high-quality brewing beer. They started with a supposedly small brewery in the US state of Pennsylvania, where they converted a former factory in Downingtown into a bar complete with a restaurant and brewery and brewed 1,725 barrels of beer a year in the beginning. Due to high demand, the company planned a second, more modern brewery in Parkesburg, Pennsylvania. The 19,700-square-metre brewhouse now produces about ten brews daily and around 225,000 barrels a year. Owing to the size of the brewery, the brewers' grains also had to be pumped over long distances.

Brewers' grains pumps: maximum reliability and long service life

As a brewery that covers such a high demand for premium varieties, the company needs systems for pumping the brewers' spent grains that offer maximum reliability, good maintainability and long service life. The unique properties of the brewers' grains pose significant challenges for the pumps. The residues of the brewing malt are usually up to 65 °C hot and have a very different moisture content. They are also very abrasive and sometimes have to be pumped over long distances. This requires unique brewer pumps that can build up very high pressure.

How to pump brewers' grains maintenance-free over long distances

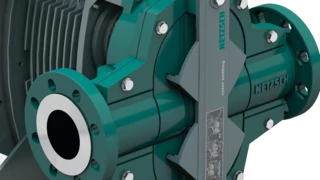

NETZSCH offers you the optimal solution for maintenance-free pumping of the brewers' spent grains. The NEMO® B.Max mixing pump in block design is equipped with stators made of elastomer, which can expand with the heat from the spent grains. To compensate, the rotor is designed with a smaller diameter to rotate with maximum power and the lowest possible torque in the stator. Thanks to the pump housing with a large, rectangular inlet hopper, removable, conically shaped stuffing chamber, and a coupling rod with a transport screw, the progressing cavity pump guarantees optimum product feed into the conveying elements, regardless of pressure and viscosity.

The pump is also equipped with dry-running protection. This continuously monitors the surface temperature of the stator while the pump is in operation. If the preset switch-off temperature is exceeded, for example, due to dry-running, a signal is sent to the motor control, and the pump switches off automatically. In this way, you prevent damage when pumping brewer's grains. At the brewery in Parkesburg, the brewer's spent grain pump runs for four to five years without maintenance work or replacement of the stator. The spent grains must be pumped over 76 meters to the brewery's spent grains silos.

NEMO® B.Max mixing pump

- Medium: Spent grain

- Throughput: Volume 16 m³/h

- Rotations speed: 100 up to 150 rpm

- Pressure: 5 up to 18 bar

- Viscosity: 10,000 cP

- Temperature: 65 °C