Sparkling Wine

Increasing Effectivity of Pumping Sparkling and Semi-sparkling Wine

How to benefit from NETZSCH when pumping sparkling and semi-sparkling wine

Gentle conveying, high metering accuracy and hygiene are precisely the requirements for pumping sensitive media such as sparkling or semi-sparkling wines. In general, carbonated wines, in particular, pose significant challenges for global conveying systems. An upper Italian winery also faced this problem when they came across NETZSCH Pumps & Systems.

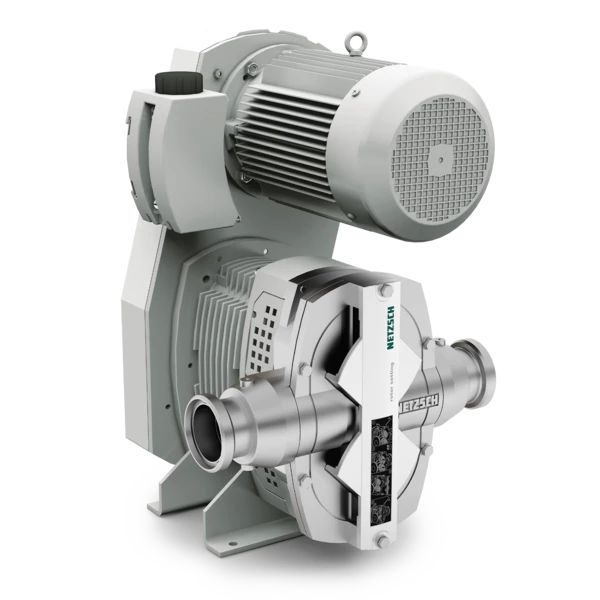

In the food industry, the oil-free TORNADO® T.Sano® rotary lobe pump gently conveys sensitive products such as sparkling and semi-sparkling wines, while metering them extremely accurately.

Due to their sensitivity, wines are already considered a difficult product to pump. Carbonated wines also open up completely different problem areas.

Individual Consulting

Challenges when pumping sparkling and semi-sparkling wine

Due to their sensitivity, wines are considered a difficult medium to convey anyway. However, carbonated wines open up other problem areas. Whether sparkling or somewhat bubbly, carbonic acid bubbles provide an extraordinary tingling sensation in sparkling wine, for example. The amount and pressure of the CO2 are, therefore, not left to chance but are characteristic of each variety. They even determine the typification. Only wines with more than three bar of excess carbon dioxide pressure at 20 °C may call themselves sparkling wines (spumante), while wines between one and two and a half bar are sparkling wines (frizzante). To ensure the desired carbon dioxide content and pressure, the production process at the Piedmont winery, right up to bottling, works under controlled pressure conditions. Nitrogen is used to aid this, generating between zero bar for still wines and five bar for particularly sparkling wines, depending on the variety.

What you need to know when pumping sparkling and semi-sparkling wine

In addition to the demand for hygiene and high metering accuracy, one of the most significant challenges for pumps in producing sparkling and semi-sparkling wines is the prevention of foaming. Pumps must, therefore, refrain from mixing the wines under any circumstances. In addition, pulsation and the associated foam formation must be avoided, which can render entire batches unusable in extreme cases. To ensure this, pumps must gently convey the sparkling and semi-sparkling wine. NETZSCH offers you a pump for precisely this purpose, which is also particularly easy and quick to clean. This allows you to meet even the highest demands for food safety quickly.

Sparkling and semi-sparkling wine: Gentle pumping and precise dosing

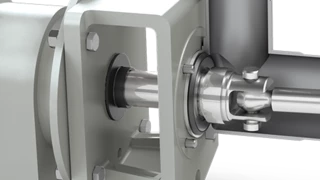

Therefore, the large upper Italian winery relies on a particularly low-pulsation and hygienically safe rotary lobe pump from NETZSCH. The oil-free TORNADO® T.Sano® all-metal rotary lobe pump offers gentle pumping and precise metering. Since pumping is purely based on the positive displacement principle, pressure fluctuations or shear forces are eliminated. The rotary lobe pump does not generate any pressure on the sparkling and semi-sparkling wine but only conveys against the existing counter-pressure. In this way, you preventively counteract a reduction in quality. In addition, the specially designed inner geometry of the delivery chamber keeps any pulsation at a superficial level. This enables you to have a continuous delivery flow without the turbulence that could lead to foam. This reliably preserves the organoleptic characteristics of the respective wine.

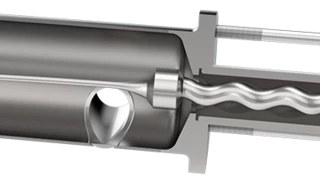

The function of the pump is based on two rotary lobes, which counter-rotate, thus transporting the product from the suction to the pressure side. Since pumping is performed purely according to the positive displacement principle here, there is no possibility of pressure fluctuations or shearing forces. "In actuality, this type of pump does not pressurize the product but rather only pumps against the existing counter-pressure – 1 to 8 bar in this case", says Alessandro Modenini, the NETZSCH sales representative responsible for the project. A gentle, continuous delivery without any turbulence that could lead to foam is guaranteed and the organoleptic characteristics of the respective wine remain reliable.

An additional advantage of this technology is the constant flow rate, which can be precisely monitored in contrast with pumping with gas pressure. The delivery volume does not depend on the viscosity or consistency of the product and is determined solely by the speed of the rotary lobe. In this way, the product can be dosed precisely using the speed control, which simplifies bottling and minimizes production fluctuations. The rotary lobe pump also is self-prim so that storage containers like wine tanks can be emptied almost completely without great effort. Since excess must be disposed of, this improved yield could noticeably increase the production profits of the winery in comparison with the previous method.

To meet food safety guidelines in addition to the economic aspects, all components used in the T.Sano® rotary lobe pump that come into contact with the product are designed in stainless steel. Forced ventilation was also integrated for safety reasons to protect the motor against overheating. T.Sano® has therefore been running malfunction-free at the Piedmont company for a year and pumping 7 to 10 m³ wine, both semi-sparkling and sparkling wine an hour at low speed.

TORNADO® T.Sano® all-metal rotary lobe pump

- Medium: Sparkling and semi-sparkling wine

- Delivery pressure: 1-8 bar

- Carbon dioxide pressure: 1-3 bar

- Nitrogen pressure: 0-5 bar