Mayonnaise

With This Pump, You Can Increase the Quality of Mayonnaise Production

How to pump mayonnaise gently with low shear in the future

Do you want to increase the quality of your mayonnaise and production efficiency? We show you how to pump mayonnaise in a particularly product-friendly manner and with low shear.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems offers you innovative solutions for the food and pharmaceutical sectors worldwide. In doing so, we promise you Proven Excellence - outstanding performance in all areas.

Individual Consulting

Challenges in pumping mayonnaise

Worldwide consumption of mayonnaise even exceeds that of ketchup. In Germany, each household consumes an average of two kilograms. The increasing demand requires a correspondingly high level of efficiency in industrial production. Unique pumps are needed to ensure the quality of mayonnaise because the production process is complicated. Egg yolk, salt, oil, spices, starch and water, form the basis of mayonnaise. The most critical aspect is to ensure an even distribution of oil droplets in the water and to prevent the emulsion from breaking into a water-in-oil mixture. This mixture would not be able to be whipped into the desired cream afterwards. Instead, it would have the consistency of salad dressing.

Pumping mayonnaise: Gentle and efficient at the same time

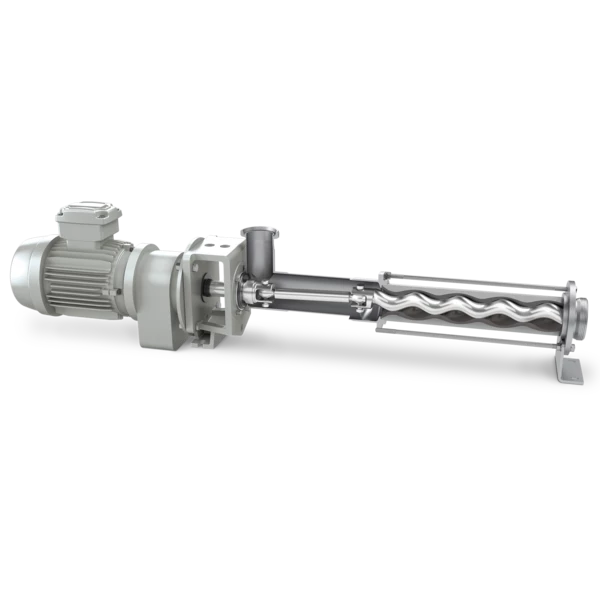

Many pumps quickly reach their limits with gentle conveying and high efficiency in the production of mayonnaise, unlike NEMO® progressing cavity pumps from NETZSCH Pumps & Systems. The global specialist in complex fluid management offers you the optimal solution for pumping mayonnaise. Using a NEMO® BH hygienic pump in a compact block design, you can pump mayonnaise gently and simultaneously, increasing your production’s efficiency. In this way, there is no doubt you will be able to meet the ever-increasing demand. NEMO® progressing cavity pumps are based on the rotor-stator principle, which enables low-pulsation running. This feature, together with a low rotational speed, guarantees gentle conveying of the product and intense shearing, which is a decisive factor for the quality of the mayonnaise.

How to pump mayonnaise while maintaining the highest hygiene standards

Another critical point in the production of mayonnaise is hygiene. Since mayonnaise is a highly sensitive foodstuff due to the egg yolk, it contains, the highest hygiene standards apply to the entire conveying system. Keeping this in mind, the NEMO® hygienic pumps are designed without dead space. Therefore, no product components can settle in the housing. This even applies to the open, patented, sanitary joints. The dead space-free design of the hygienic pump meets the highest hygienic standards in the food sector. All surfaces in contact with the product are made of polished stainless steel. This makes it more difficult for the product to settle and makes cleaning much more accessible.

NEMO® hygienic progressing cavity pumps are based on the rotor-stator principle: In these, there is continuous conveyance from the inlet to the discharge side with the rotation of the product. Together with the pump's low-pulsation operation and low speed, gentle conveyance is achieved which keeps the product smooth and has a low shear rate – this is a crucial factor for the quality of the mayonnaise. Furthermore, the NEMO® hygienic progressing cavity pump is designed for the high hygiene requirements of the food industry. With a view to this, NEMO® hygienic pumps have been designed to have no dead spaces, so that no product components can be deposited in the housing. This even applies to the open hygiene joints. All surfaces of the NEMO® hygienic pump that come into contact with the product are made of stainless steel and polished, to prevent the product adhering and to facilitate CIP cleaning. To achieve the required flow speed during CIP cleaning, NEMO® hygienic pumps have additional flushing supports. This means it is even possible to sterilize the system.

NEMO® BH hygienic pump in compact block design

- Medium: Mayonnaise

- Capacity: 0,1-30 m³/h

- Pressure: Max. 4 bar