Ceramic Slurry

Do You Want to Increase Your Service Life When Pumping Ceramic Slurry?

How to pump abrasive, viscous ceramic slurry reliably and efficiently

Do you work in the ceramics industry and use a progressing cavity pump to fill and transfer fireclay and ceramic slurry? In this case, you are certainly also struggling with the problem of low service life, high maintenance costs and unplanned downtimes.

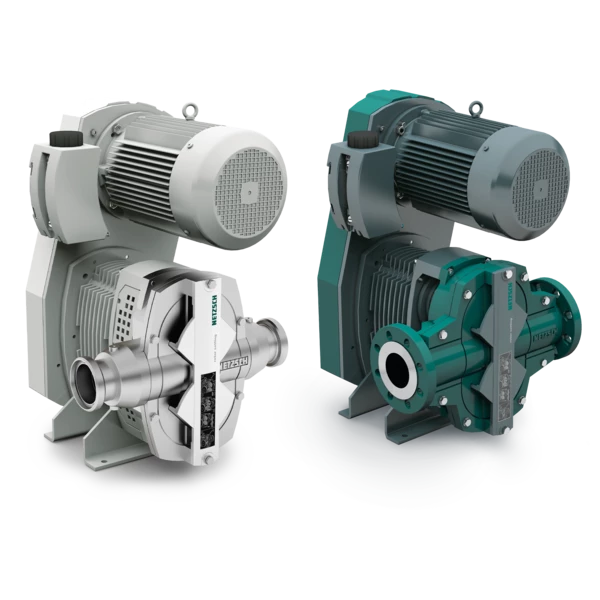

The special design of the TORNADO® T.Proc® rotary lobe pump ensures a six-fold service life when pumping abrasive and highly viscous ceramic slurry in the chemical industry.

In the ceramic manufacturing process, a number of shaping processes are available which can be categorized into the basic types of pressing, plastic forming and casting.

Individual Consulting

Are you tired of changing your ceramic slurry pump every three months?

For ceramic slip casting, for example, a watery suspension is poured into a porous mold which drains liquid from the slip. This produces a solid layer, the so-called cullet. Slip and grog are initially kept in storage tanks. Due to the viscous and abrasive product, ceramics manufacturer used a NEMO® progressing cavity pump from NETZSCH for filling and recirculating ceramic slip until 2013. This model was initially recommended due to the very positive experiences with mineral suspensions, such as plaster, mortar or concrete primer.

Challenges to consider when pumping ceramic slurry

Reasons for the high wear of the ceramic slurry pumps can be found in the properties of the medium. For example, the composition of the ceramic slurry can change over time, especially if it is stored for a more extended period. This leads to variations in the flow properties of the slurry and significantly affects your pump performance. Another challenge of fireclay and ceramic slurry is its high abrasiveness. The medium acts like sandpaper on the rotor and stator. The resulting high wear of the pump components shortens the service life and increases your maintenance effort. In addition, ceramic slurry has a higher viscosity compared to other fluids. This leads to difficulties when pumping, especially if the pump is designed for less viscous liquids. It is essential to select a pump suitable for handling viscous materials. As a partner for pumping complex media, NETZSCH and the ceramics manufacturer found the solution optimally adapted to the unique properties.

With this ceramic slurry pump, you can increase your service life sixfold

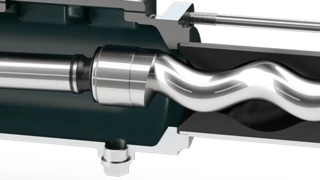

The choice fell on a TORNADO® T.Proc® rotary lobe pump. The T.Proc® is specially designed for high robustness and long service life with minimal wear. With this rotary lobe pump, you can pump even highly abrasive material mixtures such as fireclay and ceramic slurry without any problems. The innovative combination of operating principles and particular material pairing developed by NETZSCH makes this possible. While other pump manufacturers usually have elastomer lobes rotating in a metal housing and thus subject to high dynamic loads, rotary lobes made of a particularly robust, hardened steel are used here. In addition, the pump interior is lined with an easily replaceable rubber liner. Thus, wear is significantly reduced. The rotary lobe pump also offers you substantially higher efficiency. Therefore, you can increase your service life sixfold when pumping ceramic slurry or other abrasive media - and reduce your costs simultaneously. The protective housing insert made of acrylonitrile butadiene rubber (NBR) can be easily removed separately and replaced cheaply.

To increase the efficiency of the system, NETZSCH therefore suggested the change to a pump from the TORNADO® T2 range: the rotary lobe pump T.Proc® is specially designed for a long service life with minimum wear, so that it can also convey highly abrasive compounds without problems. This is made possible by the combination of the operating principle and a special material pairing, which is only offered by NETZSCH: Whereas other pump manufacturers normally have elastomer lobes rotating in a metal housing and exposed to a high dynamic load, this unit uses steel rotary lobes while the inside of the pump is lined with a changeable rubber insert. This is reflected in accordingly lower wear and higher efficiency. The protective housing liner made from acrylonitrile butadiene rubber (NBR) can easily be removed as a separate part and replaced cost-efficiently. Overall, this achieves a six times longer service life and therefore substantial cost savings for abrasive product.

The innovative drive concept of the TORNADO® T2 range is also characterized by a long service life: A belt drive, toothed on both sides, replaces the timing gear which was previously common for rotary lobe pumps. Due to its complex design, this was prone to malfunctions and defects. In contrast to this, the new drive technology can even survive damage or blockages without major damage. The double-sided toothed belt is not only used for transmission of forces from the motor to the shafts, however, it also synchronizes the rotating motion of the lobes. This dual function has the great advantage of simplifying the overall drive design considerably, which increases operational reliability while also saving installation space. In conjunction with the motor being flanged onto the top of the pump chamber, this provides one of the most compact pumps on the market.

TORNADO® T.Proc® rotary lobe pump

- Medium: Medium: Ceramic slurry and fireclay

- Pressure: 4 to 5 bar

- Flow rate: 15 to 25 m3/h