Sauces

Empty Your Tanks in the Sauce Kitchen With Almost No Residual Quantity

How to increase efficiency while maintaining the highest hygienic standards

Everyone knows the problem: When containers or tanks have to be decanted in the kitchen, sometimes hot medium splashes all over the room, resulting in slippery basements. But how can you prevent this to minimise material losses and ensure the occupational safety of your employees?

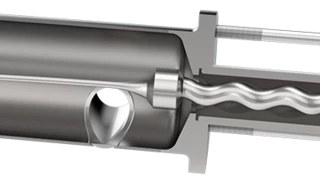

With the help of the TORNADO® T.Sano® rotary lobe pump, containers in the food industry can be emptied with virtually no residual volume.

When it comes to conveying systems in the foodstuff industry, the main focus is primarily on hygiene, cleanability and compatibility with food.

Individual Consulting

Meats Industry & Slaughterhouses

The industry for slaughtering and processing animals began in Cincinnati, OH in the US in 1845. It was with the invention of refrigerated railway cars in 1878, however, that Chicago was able to achieve the distinction of becoming the center of America's meat processing industry. It is from here that the methods spread worldwide.

Challenge accepted

Of course, without drying, smoking or curing, cooling only provides limited preservation time so in the US, the first consumer protection laws were established in 1906 to assure hygienic handling. Strict legal regulations were applied to production, storage, processing and preparation of meat and offal products. Machines and components used in the processing are strictly regulated to ensure hygienic handling and cleanability.

How to increase efficiency when emptying tanks in a sauce kitchen

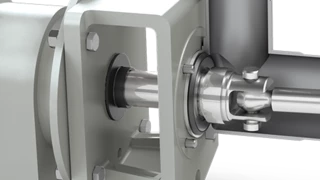

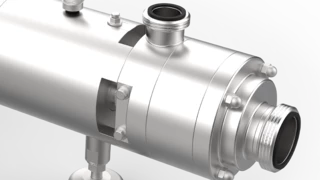

The TORNADO®rotary lobe pump offers you countless advantages compared to a lift-and-tilt system. Thanks to the belt drive, the T.Sano® operates completely oil-free and thus poses no risk of contamination. In addition, it is particularly low-maintenance. The rotary lobe pump is also the optimum solution in matters of hygiene. The completely smooth housing is virtually impervious to dirt and dust. This is made possible by the compact and space-saving design, which avoids corners, edges or dead spaces. On the other hand, the T.Sano® offers you effortless cleaning (CIP - "Cleaning-In-Place-Procedure") and sterilisation (SIP - "Sterilisation-in-Place-Procedure"). You can clean the system in a circular or continuous process without prior disassembly.

Excellently solved

NEMO® PUMPS are engineered to meet the EHEDG directives (European Hygienic Equipment Design Group) or the QHD directives (Qualified Hygienic Design). Materials are approved by the FDA (Food and Drug Administration) and BfR (Federal Institute for Risk Assessment). Along with this, NEMO® hygienic and aseptic pumps meet the regulation of the 3-A Sanitary Standards in the US and are certified according to GOST-R (Russian Certificate of Conformity).

While the hygienic and aseptic versions of NEMO® PUMPS are used on the processing side, many are employed on the disposal side as well.

TORNADO® T.Sano® rotary lobe pump with smooth surface

- Medium: Sauce base

- Capacity: 70 m³/h

- Pressure: Max. 12 bar

- Speed: 800 rpm