asphalt

Do You Want to Increase Efficiency When Pumping Asphalt?

This is how to permanently reduce wear when pumping asphalt

Choosing the right pump is crucial for the efficiency of your system. But the variety of different pump types is enormous. Identifying the right pump type for an application can quickly become challenging. A Dutch road repair company faced the same problem.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems has a broad product portfolio and the expertise to support you in choosing the right pump solution from the start. Our experts will work with you to find the optimum pump for your application. We will show you how to avoid unplanned downtimes and sustainably increase your efficiency when pumping asphalt.

Individual Consulting

Pump asphalt on-site and clear the road for traffic in less than an hour

Whether car drivers, motorcyclists, lorry drivers or cyclists, everyone knows about the problems road potholes cause. According to the federally owned Autobahn GmbH, in 2023, there will be 552 road works on German motorways alone, causing traffic jams and loss of time. But not every closure necessarily has to last long. To reopen the streets for traffic as quickly as possible in the case of minor road damage, a Dutch company has developed a unique technology. A fast-curing synthetic resin-based repair asphalt is mixed and applied directly on-site on a particular vehicle. The major advantage of this method is that the road can be cleared for traffic after less than an hour.

Challenges to consider when pumping asphalt

“To get the special mortar ready for use, the cold asphalt mixture is stored in a tank with an agitator and pumped through the mixer, in a special vehicle directly on site”, explains Max Waser, Engineer Internal Sales at NETZSCH Pompen Nederland. “The same vehicle then spreads gravel from a reservoir over the cold asphalt.” Until April 2018, a rotary lobe pump was used for the first step of pumping the mixture of resin, sand and silver sand. The pump had to be operated at speeds of around 250 to 300 rpm and suffered high levels of wear due to the highly abrasive product. “This especially affected the elastomer lobes – in the end the company for the application of road surface coatings had to replace them every two to three weeks, so the vehicle was often out of operation”, explains Waser.

Reduce your downtime with this asphalt pump

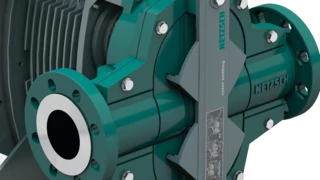

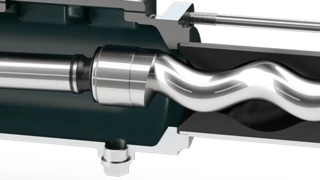

Choosing the right pump depends on many factors, such as the pumped medium, flow rate, pressure, viscosity or temperature. After thoroughly analyzing the requirements and operating conditions, NETZSCH advised the Dutch company to replace the rotary lobe pump previously used to convey the cold asphalt with a NEMO® progressing cavity pump in FSIP® design. Progressing cavity pumps offer gentle conveying with little shearing and pulsation. This makes the NEMO® particularly suitable for pumping cold and viscous asphalt om the repair vehicle. A large pump model has been selected which makes optimum use of the space on the vehicle and, at the same time, ensures the lowest possible rotation. This allows for prolonged and precise pumping at 50 to 75 revolutions per minute. At the same time, the delivery rate could be doubled to one cubic meter per hour. This significantly increased the efficiency of the plant of the Dutch specialist for road repairs.

Those responsible therefore decided for this application to replace the previous rotary lobe pump with a more suitable progressing cavity pump with lower pulsation and less wear. A NEMO® progressing cavity pump of the type SY from NETZSCH was selected: Due to its displacement principle allowing smooth pumping with low shearing and pulsation, this pump type is ideal for use on the specialized repair vehicle to convey the cold asphalt which has a temperature of 20 °C and a viscosity of 7,000 to 10,000 mPas. “We selected the largest possible pump model for our customer which makes optimum use of the space on the vehicle and also ensures low rotation”, explains Waser. “This allowed us to achieve values of around 50 to 75 rotations per minute, meaning particularly slow and precise pumping.” However, the capacity of the pump was doubled to 1 m³/h at this speed.

The NEMO® progressing cavity pump from NETZSCH has now been used by the Dutch specialists since April 2018. With a pressure of 5 bar, it pumps 1 Cubic meter of the abrasive resin/sand/silver sand mixture per hour. Thanks to the stainless steel components and the EPDM elastomer components, the pump has been running without problems so far. That it works without malfunctions in contrast to the previous model has not only positive effect on the operating hours of the machine, but also to the curing time of the repair asphalt: “If the components of the product are mixed well continuously, which is supported by the coupling rod with mixing elements, the mortar now needs less time to fully cure. So the road can be cleared for traffic even sooner”, explains engineer Waser.

NEMO® progressing cavity pump in FSIP® design

- Medium: Mixture of resin, sand and silver sand

- Speed: 50 to 75 rpm

- Flow rate: 1 m³/h

- Temperature: 20 °C

- Pressure: 5 bar

- Viscosity: 7,000 to 10,000 mPas